DMAIC (Define, Measure, Analyze, Improve, Control) Methodology

- Paul Gravina

- Oct 29, 2017

- 1 min read

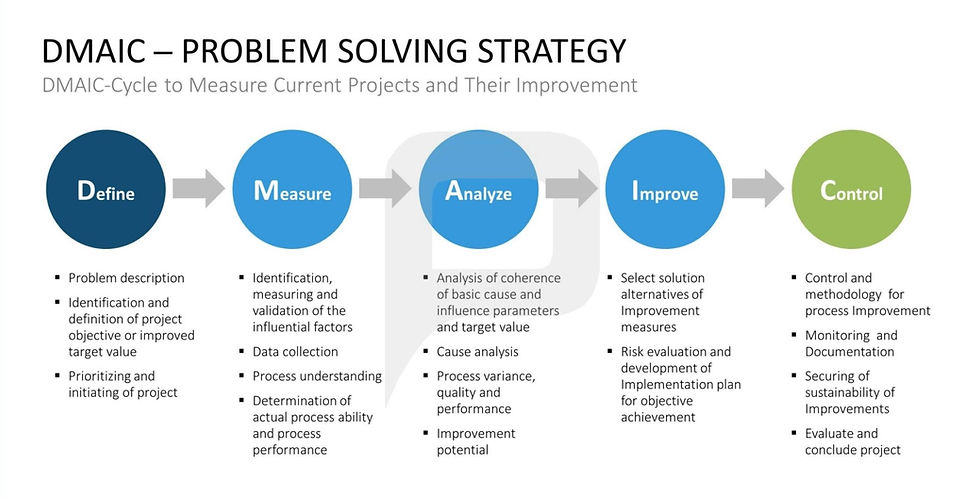

The DMAIC (Define, Measure, Analyze, Improve, Control) methodology, which I discussed in earlier postings is used when a product or a process already exists in a company. This is like an extension of the methodology that will exist in the organization, you can build on the methodology but you will implement these methodologies when a NEW process or a product (application) has to be developed.

DFSS is an acronym for Design For Six Sigma.

DFSS describes how to implement the method of using tools, training, measurements, and verification so that products and processes that are designed, meet the demands of Six Sigma.

A more specific version of DFSS is DMADV, i.e., Define, Measure, Analyze, Design, and Verify. DMADV uses Six Sigma principles in product/process design in a new business process.

DFSS covers the DMADV framework for the design of processes; using statistical techniques, simulation software to analyze variation and risks, and performing Design of Experiments.

DMADV methodology covers the following phases:

D- Define the project goals of the design activity consistent with the customer demand

M- Measure and determine customer needs and specifications and identify CTQs, product capabilities, risk assessment and so on

A- Analyze the process options to meet the customer needs and design alternatives, create high-level design and evaluate design capability

D- Design the process to meet the customer needs, optimize design, and simulations are also involved in this phase

V- Verify the design performance and ability to meet customer needs, set up pilot runs, implement production process Similarities between DMAIC and DMADV

Comments